Working towards Sustainable Fashion in the Print-on-Demand Industry

Last year, I decided to declutter my closet. I thought it would be an easy game because I don’t buy a lot of clothes, but in the end it took me several days to achieve my goal—a neat, organized selection of apparel that I wear regularly. Marie Kondo would be proud.

But opposite my tidy closet was a pile of unwanted clothing that definitely didn’t spark joy. Even after donating the still-wearable apparel and recycling the rest, most of the items will end up in landfills anyway.

My garbage pile is a small drop in the ocean of waste the fashion industry generates. Everything from the amount of clothing we discard to discouraging statistics about fashion being one of the main offenders in pollution shows a deep problem within the industry.

As an on-demand drop shipper, RIGHT CROSS is part of this industry. And even though on-demand production is ahead of the fast fashion brands in terms of sustainability, we don’t want to stop there. That’s why sustainable fashion—a movement that wants to advance the fashion industry towards more ecological processes and social justice—is on RIGHT CROSS's agenda.

Let’s talk about how sustainable fashion wants to change the industry, why such a reform is needed, and what RIGHT CROSS is doing to be part of the movement.

Sustainable fashion is the new norm

Sustainable fashion is a scientific, data-driven movement that aims to make sure that our clothes are manufactured, sold, and used in the most sustainable way possible. It wants to change the industry on all levels of the supply chain, starting from sourcing the materials to producing and selling apparel.

What’s more, sustainable fashion doesn’t just champion changes that are good for the environment. It also aims to address the social issues that concern the workers of the industry, such as low wages and poor working conditions.

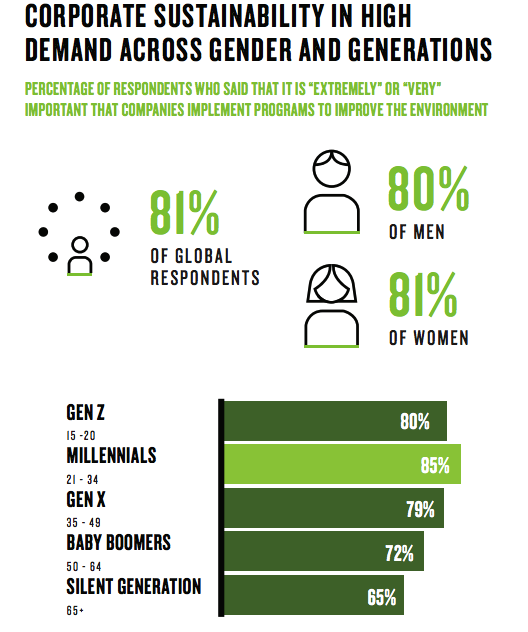

I find it promising that the call for sustainable fashion comes from customers. People are aware of the industry’s problems and they want to do better, demanding that companies follow along.

Retail chains are realizing they also have to comply with what people are asking for. But brands have to understand that they have to go deeper than simply using marketing buzzwords to appease an eco-conscious audience.

For example, in 2019 the UK fashion retailer Boohoo announced they’d stop using wool in a bid to be more environmentally friendly. They reversed the decision a couple of hours later after being heavily criticized by their customers, partly because wool is a relatively sustainable fiber.

Despite the shaky start, Boohoo has since shown that they care about meaningful improvements. Last year, the retailer released their first recycled collection, and they’re now more transparent about their social responsibility initiatives.

Tricking customers into thinking you’re sustainable—aka greenwashing—won’t do. Become sustainable to actually drive change, not just to follow (or pretend to follow) customer trends.

To understand why working together towards sustainable fashion is necessary, it’s important to be aware of the main issues in the world of fashion.

The current state of the fashion industry

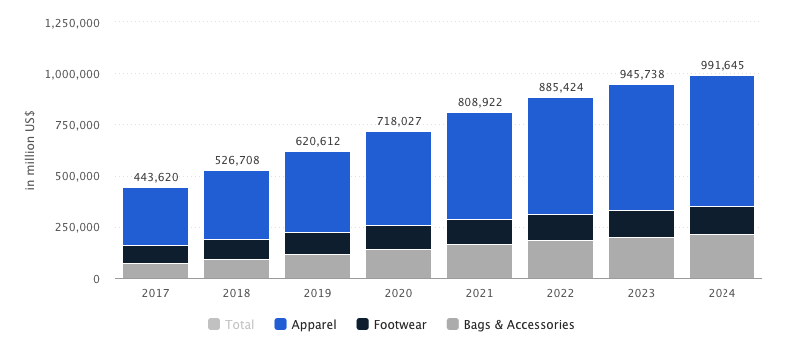

The worldwide revenue of the fashion market is predicted to rise from $481.2 billion in 2018 to $712.9 billion in 2022. That’s good news for shop owners, but it could become a worrying statistic for the environment and, by extension, all of us.

Luckily, the fashion world has never been more eager to become more sustainable.

The main problem to tackle is the pollution created by producing and selling apparel. To understand the extent of the issue, let’s look at the product life cycle for one of the fashion industry’s favorites: the white cotton t-shirt.

Cotton apparel is comfortable, durable, and breathable. Cotton is also relatively cheap to grow and harvest, so it comes as no surprise that it’s the most widespread non-food crop in the world.

Unfortunately, it has some drawbacks. Cotton farmers use pesticides, insecticides, and fertilizers. These mix with the water and drain into soil, affecting the biodiversity of the land and limiting fresh drinking water.

Growing enough cotton for a single t-shirt takes up to 731 gallons of water (that’s enough for one person to drink for 3.5 years). In comparison, producing enough polyester for a t-shirt requires 4 gallons of water.

After cotton is harvested, it’s sent to a textile mill where it’s manufactured into a rough gray fabric. The fabric is then bleached, dyed, and treated with chemicals to achieve the desired look—a soft, white roll of fabric that’s sent to a sewing facility and turned into t-shirts. All these production steps can lead to environmental damage because of the chemicals and water they require.

Finally, the t-shirts have arrived at your favorite retail store. You buy one and wear it. But what happens to the rest of the t-shirts you saw on the rack? The ones that don’t get sold often end up in landfills or get burned, resulting in more emissions and pollution.

But now that the fashion industry and its customers are aware of these problems, the enthusiasm to change towards the better is at an all-time high. Everyone is looking for solutions that will turn the industry around, so that every cotton t-shirt gets to our closets in a sustainable way.

RIGHT CROSS’s experience as a print-on-demand business

Print-on-demand (POD) services might just be one of the keys to an environmentally friendly fashion industry. Let’s explore how RIGHT CROSS’s product catalog and stock, printing techniques and equipment, and the way we run our facilities help our customers work towards owning sustainable fashion brands.

Our stock

The biggest advantage POD companies have over big fashion retailers is that on-demand produces less waste.

Traditional shopping chains produce items to sell, so they’re always manufactured in bulk to save money. Meanwhile, RIGHT CROSS only prints a product when a customer places an order for it, creating items that already have a known buyer.

This lets us avoid overproduction—excess items that don’t get sold and have to be thrown out or burned, which several retail giants do. With 92 million tons of textile going to waste in the fashion industry each year, a business model like this is a game-changer.

Waste in POD mainly comes from the items that are damaged during printing, and RIGHT CROSS’s rate for damaged items is within the industry standard.

RIGHT CROSS donates returned items to local charities and offers damaged apparel to animal shelters who can use them for their needs.

Adding sustainable products means finding sustainable suppliers. One of our long-term partners is Bella + Canvas, a clothing manufacturer with care for the environment embedded in their brand identity. Bella + Canvas uses solar energy, limits water use, and recycles waste by-products to make sure their products can sport the eco-friendly tag.

Direct-to-garment (DTG) printing is more sustainable than older apparel printing methods, such as screen printing. Not only does screen printing use a lot of water and plastisol inks that don’t biodegrade, but it’s also tended towards bulk orders which can lead to overproduction. In comparison, DTG printing is more eco-friendly because items get printed only when there’s already a customer for them.

The inks we use for printing are water-based and free of harmful chemicals. We take care to dispose of any left-over ink according to our supplier guidelines, so we’re not harming the environment.

While there are still issues to address, print-on-demand is gradually becoming a less wasteful and more sustainable alternative to the traditional bulk manufacturing and selling model. And that’s good news for both brands and consumers.

What comes next

People need clothes. Fashion is a beloved industry that’s part of our identity and economic growth despite its environmental and social flaws. But in order to treat the environment and people who live here better, the industry has to step up.

As a company, we’re taking responsibility for the impact our business has on the world and working to help our customers become more sustainable. And we’re excited to share this journey with you!

To get inspired for the next steps, let us know in the comments the way your favorite brands are participating in the sustainable fashion movement.

Leave a comment